Detergent Shampoo Liquid Soap Making Machine Mixer Machine

Basic Info.

| Model NO. | CM-JBJ-500 |

| Certification | CE, ISO |

| Application Area | Chemical |

| Layout Type | Verticle |

| Mixing Drum Shape | Drum |

| Additional Capabilities | Mixing, Heating |

| Operating type | Continuous Operating |

| Condition | New |

| Homogenizing Speed | 3000 Rpm |

| Control System | PLC & Button Control |

| Heating Method | Steam or Electric (Optional) |

| Suitable for | Creams, Milk, Gels, Balms, Lotions, Ointments, Too |

| Production Time | 30-35 Days |

| System | Hydraulic Lifting System and Mixing System |

| Supply Power | Customer Design |

| Stirring Speed | 0-65 Rpm |

| Homogenizer Motor | Siemens or ABB Only |

| Products Name | Detergent Shampoo Liquid Soap Making Machine Mixer |

| Voltage | 380V/220V |

| Capacity | 100L-5000L |

| Transport Package | Polywood Case |

| Specification | 500L |

| Trademark | COSMATI |

| Origin | Guangzhou |

| HS Code | 8474900000 |

| Production Capacity | 25 Sets/Month |

Product Description

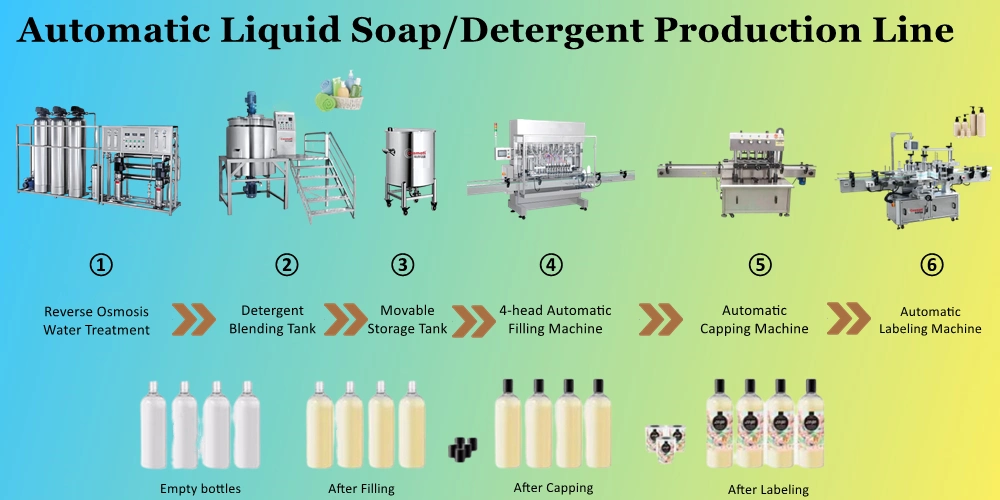

Detergent Shampoo Liquid Soap Making Machine Mixer Machine

Introduction:

Shampoo blending machine is our latest product research and developed by our company which combined overseas superior emulsifier experience with domestic cosmetic enterprise feedback.

This machine adopts imported stainless steel, scientific homogenizing system, reasonable scraper blending to ensure equivalent homogenizing and make product more smooth, even and bright.

Feature:

1, the equipment consists of cabinet and blending tank.

2,There is advanced scraper blending machine, with the working of eccentricity, the PTPE (F4) composite plate touch the boiler correctly and solve the problem of sticking materials. The ideal stepless speed adjustment device, can adjust rotation within 0-60rpm willingly.

3, advanced homogenizing system imported from USA ROSS Company, the homogenizer is in the bottom to ensure homogenizing material even with small productivity. The sealing adopts recycled water cooling system and can work long time, conquer homogenizing problem regarding to high viscosity materials. A frequency conversion speed adjustment controller to satisfy kinds of complicate ingredients (Emulsifying capacity 3 times per minute) upper homogenizer as option to work with upper homogenizing and emulsifying so that the material emulsifying effect is better; product is more bright and luminous.

Usage:

Our blending reacting boiler is mainly suitable for preparation of liquid detergents(such as cleanser essence,shampoo and shower cream etc)

Integrating blending ,dispersing ,heating and cooling etc. functions,the reacting machine is an ideal device for liquid perparation in various factories .

Technology parameters:

| Model | Capacity(L) | Mixing Power | Mixing Speed | Homogenizing power | Homogenizing Speed | Heating Method |

| CM-JBJ-500 | 500 | 2.2 | 0-65 | 5.5-7.5 | 3000 | Steam Heating or Electirc Heating(Optional) |

| CM-JBJ-1000 | 1000 | 4 | 0-65 | 7.5-11 | 3000 | |

| CM-JBJ-2000 | 2000 | 5.5 | 0-53 | 11-15 | 3000 | |

| CM-JBJ-3000 | 3000 | 7.5 | 0-53 | 18 | 3000 | |

| CM-JBJ-5000 | 5000 | 11 | 0-42 | 22 | 3000 | |

| CM-JBJ-10000 | 10000 | 15 | 0-42 | 30 | 3000 |

Detailed Photos

Company Profile

We are a cosmetic machinery manufacturer which professional in researching and developing, producing cosmetic machines. Through the agency of South Korea, Japan, Italy,equipment brand, we have deposited leading technology and applied it to our products.We focus on color cosmetic fields and cosmetic fields and provide the complete set of solutions for your company.

Our main products including Vacuum mixer homogenizer,mixer machine,cosmetic filling machine,perfume filling machine,lip gloss filling machine ,mascara filling machine,lipstick filling machine and so on. We provide fair price with competitive products.

Excellent,Professional,Competitive products and good service are provided. Dedicate QC team is responsible for quality control from start producing to delivery to customers' side. Every product is carefully verified before delivery to customer, as well as detailed inspection record to provide accurate after-sales service.

Warranty:

-All COSMATI machines are under 1 years warranty period, (but improper operation, normal spare

parts consumption are not within this scope)

- Even over 1 year, we will support for maintenance, for small problem to send spare parts to replace

or online instruction, for big problem we can send engineer if client request, and client in charge of

engineer's round ticket and accommodation.

Inspection:

- Engineers not available for on-site installation abroad, we're able to do

on-line installation services and suppy video/pictures for supporting clients installation.

FAQ

1. Why choose COSMATI Brand?

1-We have over 15 years import and export experience on cosmetic and color cosmetic fileds.

2-Our factory is located in Guangzhou and another one is in Jiangsu province,more than 200 workers in our factory.

3-Supply one stop station service for designing workshop, workshop layout, selecting machines and installation(one stop solution).

4- Professional in researching and developing, producing cosmetic machines.

5-Through the agency of South Korea, Japan, Italy,equipment brand, we have deposited leading technology and applied it to our products.

6-Excellent,Professional,Competitive products and good service are provided.

7-Quality Complete Cosmetics Equipment Solution Supplier.

2.Can you customize machine ?

As a professional machinery manufacturer for more than 15 years,we have skilled OEM technique.

3. What about after sale service?

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

When machine has problem, We will solve basic questions by telephone, email, whatsapp, wechat and video call.Customers showing us the picture or video of the problem.

If the problem can be easily solved , we will send you solution by video or pictures. If the problem out of your control, we will arrange engineer to your factory.

4. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise that our wooden packaging is strong enough and safety for long delivery.